Magnetic levitation vacuum pumps have sparked a wave of energy-saving transformation in the paper industry. After replacing the original water ring vacuum pump with two magnetic levitation vacuum pumps, a pulp and paper enterprise with an annual output of one million has achieved stable and almost maintenance free operation of the equipment, saving more than 30% of electricity compared to the original system, saving 2.09 million kWh annually, equivalent to 1.02 million yuan in electricity costs. While improving production and quality, it has also achieved a dual reduction in energy consumption and maintenance costs. The 22 kW magnetic levitation centrifugal vacuum pump from Bosen Power Technology can save more than 40% energy compared to traditional Roots blowers when applied in tissue factories, and the energy-saving effect of high-speed permanent magnet centrifugal vacuum pumps can be as high as 50% or more.

- Home

- Products

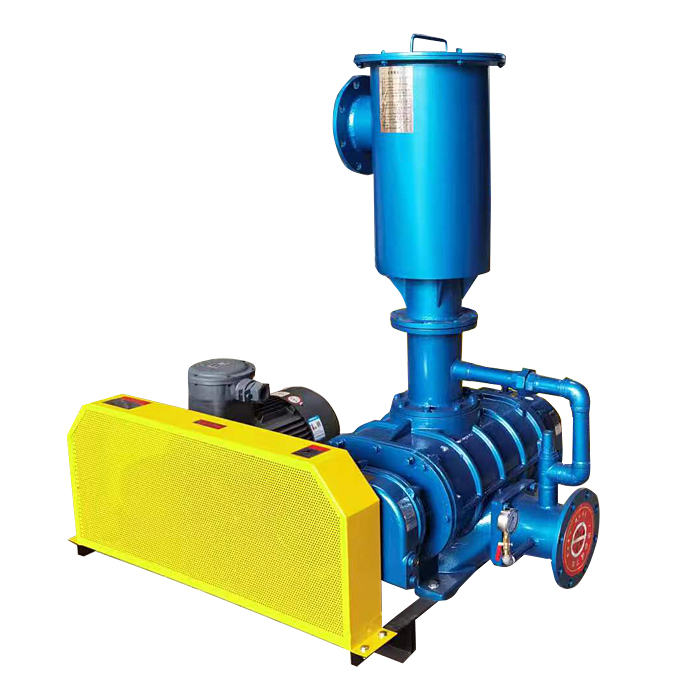

- Roots Blower

- Three Leaf Roots Blower

- Intensive Roots blower

- Roots blowers for aquaculture industry

- Roots blower for sewage treatment industry

- Roots blower for power industry

- Roots blower for special gas treatment

- Roots blower for desulfurization and denitrification industry

- Roots blower for biogas transportation

- Piston ring seal Roots blower

- Low noise Roots blower

- Pneumatic conveying system

- Rotary fan

- Negative pressure fan

- Air suspension fan

- Magnetic levitation fan

- Fan soundproof cover

- Roots Blower

- News

- Case

- Factory Show

- Contact Us

- About Us