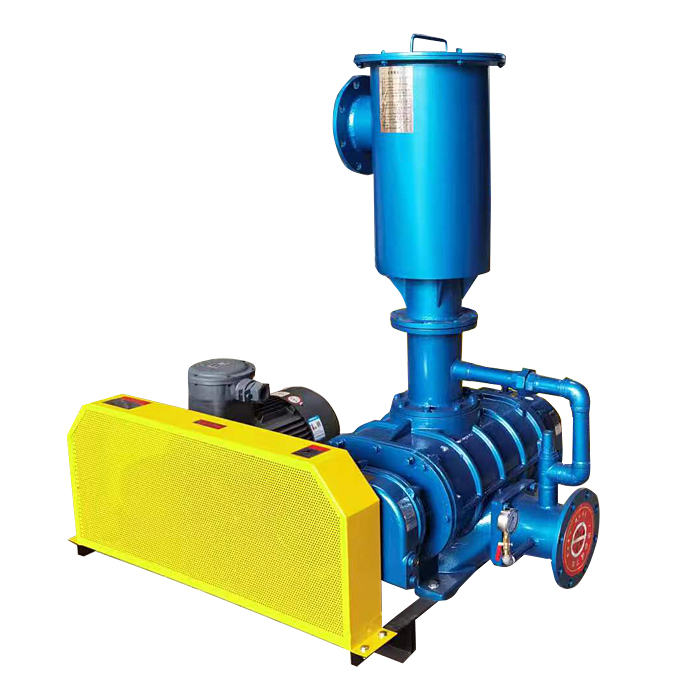

Innovative Noise Reduction Solution for Roots Blowers Creates a Serene Production Environment

Three-leaf Roots blower

Roots blower

Air suspension blower

Noise generated by Roots blowers during operation has long been a challenge in industrial settings. A groundbreaking noise reduction solution has recently emerged, offering an effective approach to tackle this issue.

This solution addresses the root cause of noise by integrating advanced sound-absorbing materials and optimized structural design. Multi-layer composite soundproofing materials are applied to the blower casing, effectively absorbing and isolating operational noise. Additionally, mechanical components within the blower are redesigned to minimize friction and vibration, reducing noise at its source.

Field tests demonstrate that Roots blowers equipped with this solution achieve noise levels below 70 decibels—down from approximately 85 decibels—meeting industrial noise standards. This improvement not only enhances worker comfort and reduces health risks but also helps companies foster better community relations by minimizing noise-related disputes.

Industry leaders have shown strong interest in this innovation, and its widespread adoption in industrial applications is anticipated.

2. Intelligent Control System for Air Suspension Blowers Enables Precision Operation and Remote Monitoring

Advances in smart technology have revolutionized air suspension blower management through a cutting-edge intelligent control system.

Equipped with high-precision sensors and powerful processors, the system collects real-time operational data such as airflow, pressure, temperature, and speed. Leveraging big data analytics and AI-driven algorithms, it dynamically adjusts parameters to maintain optimal performance.

The system also supports remote monitoring via smartphones or computers, allowing users to oversee operations and address issues from anywhere. Proactive fault alerts and diagnostic recommendations prevent unexpected downtime, ensuring uninterrupted production.

At a wastewater treatment plant, this system reduced energy consumption by 18% while boosting processing efficiency by 12%. Facility managers now effortlessly oversee multiple blowers, significantly improving operational productivity.

This innovation marks the entry of air suspension blowers into the smart era, delivering higher efficiency, cost savings, and reliability across industries.

3. Energy-Saving Upgrades for Magnetic Levitation Blowers Cut Costs for Businesses

Recent upgrades to magnetic levitation blowers have achieved remarkable energy savings, capturing widespread industrial attention.

The upgrades combine intelligent control systems with high-efficiency impellers. Sensors and algorithms continuously monitor and adjust operational parameters, while aerodynamically optimized impellers reduce turbulence and resistance, enhancing gas transfer efficiency.

At a wastewater treatment facility, upgraded blowers reduced monthly electricity costs by 25%. Smart fault detection further lowered maintenance expenses by enabling proactive repairs.

Beyond financial benefits, these upgrades contribute to sustainability goals. As technology evolves, magnetic levitation blowers will drive energy efficiency across diverse sectors.

4. Magnetic Levitation Centrifugal Air Compressors Ensure Uninterrupted Production in Textile Mills

For textile mills, production continuity is critical. Magnetic levitation centrifugal air compressors deliver unmatched stability, serving as a reliable backbone for operations.

Magnetic levitation bearings eliminate mechanical wear and vibration, extending equipment lifespan and reducing noise. Integrated smart systems monitor parameters like temperature and pressure, triggering instant alerts for anomalies. Maintenance teams receive detailed diagnostics, minimizing downtime.

In dyeing workshops, these compressors provide steady compressed air, ensuring consistent fabric quality and preventing defects caused by pressure fluctuations.

5. Magnetic Levitation Vacuum Pumps Elevate Paper Manufacturing Quality

In the paper industry, product quality is paramount. Magnetic levitation vacuum pumps play a pivotal role in enhancing paper consistency and performance.

During dehydration, these pumps deliver precise vacuum control to ensure uniform moisture removal, preventing wrinkles or warping. In coating processes, they eliminate air bubbles for smooth, even application—enhancing water resistance and printability.

For premium paper grades like art or packaging paper, these pumps meet stringent vacuum requirements, enabling manufacturers to produce high-value products and strengthen market competitiveness.

Conclusion

These innovations exemplify how advanced technologies—from noise reduction to intelligent controls and magnetic levitation—are transforming industrial equipment. Businesses adopting these solutions gain operational efficiency, cost savings, and sustainability advantages, positioning themselves as leaders in their fields. Explore these breakthroughs to elevate your production capabilities today.