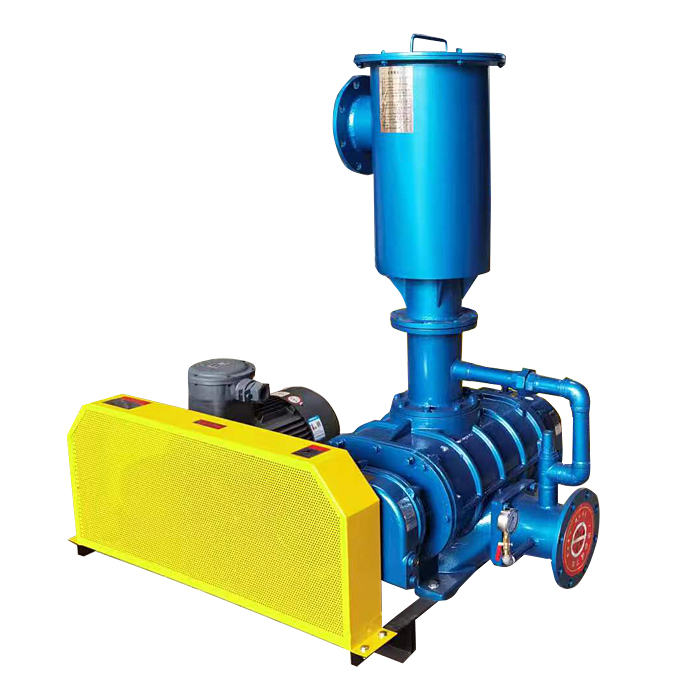

Roots blower

In the field of industrial production, Roots blower, as an important gas conveying equipment, is widely used in multiple industries such as sewage treatment, chemical industry, power, cement, etc. However, traditional Roots blowers generally suffer from high energy consumption, loud noise, and high maintenance costs, making it difficult to meet the urgent needs of enterprises for green and efficient production.

The new Roots blower has undergone comprehensive innovative upgrades to address the aforementioned pain points. In terms of energy conservation, by adopting a newly designed impeller and utilizing advanced aerodynamic principles, the flow path of gas inside the fan has been optimized, significantly reducing gas flow resistance and significantly reducing energy consumption during fan operation.

In terms of environmental performance, the new Roots blower also has outstanding performance. The R&D team has effectively reduced the noise generated during the operation of the fan by optimizing its structural design and adopting advanced sound insulation technology and materials.

Air suspension blower

The new air suspension blower launched this time adopts three core technologies: "ultra high speed direct connected motor", "air suspension bearing" and "high-precision single-stage centrifugal impeller", fundamentally solving the pain points of traditional blowers.

Noise control has always been a challenge in the field of blowers. The new air suspension blower uses air bearings and direct connection technology to reduce vibration at the root and significantly reduce noise during operation. According to authoritative testing institutions, the noise level at a distance of 1 meter from the equipment is below 80dB, far lower than the noise level of traditional blowers of 100-120dB, effectively improving the working environment and reducing interference with surrounding residents.

With the introduction of new air suspension blowers to the market, it is expected to bring new development opportunities to various industries and promote the entire blower industry to move towards high efficiency, energy conservation, and environmental protection.

Magnetic levitation blower

The new magnetic levitation blower, with multiple leading technologies, has achieved significant breakthroughs in energy conservation, noise reduction, performance stability, and other aspects. Once it was unveiled, it became the focus of the entire audience and attracted high attention from many industry experts, enterprise representatives, and media.

In the fields of industrial production and environmental protection, blowers are widely used as key gas conveying equipment in various industries such as sewage treatment, chemical industry, power, cement, etc. However, traditional blowers generally have problems such as high energy consumption, loud noise, and high maintenance costs, which not only increase the operating costs of enterprises, but also cause significant pressure on the environment.

Excellent energy-saving performance: The new magnetic levitation blower is equipped with a high-speed permanent magnet synchronous motor with an efficiency of up to 97%. Coupled with magnetic levitation bearings, it achieves non-contact and mechanical losses, and the operating efficiency can reach about 95%. According to authoritative institutions' testing, under the same working conditions, compared with traditional Roots blowers, the new magnetic levitation blower reduces energy consumption by 30% -35%.

Significant noise reduction effect: Noise control has always been a challenge in the field of blowers. The new magnetic levitation blower uses magnetic levitation bearings and direct connection technology to reduce the generation of vibration at the root, resulting in a significant reduction in noise during operation.